In the world of industrial applications, the choice of valve materials plays a crucial role in ensuring efficiency, durability, and cost-effectiveness. Among the various options available, the PVC butterfly valve has emerged as a preferred solution across multiple sectors. According to a recent market study by Research and Markets, the global butterfly valve market is projected to grow significantly, primarily driven by the increasing demand for lightweight and corrosion-resistant components in chemical processing and water treatment facilities. The benefits of utilizing PVC butterfly valves are compelling, making them a top choice for engineers and procurement specialists alike.

One of the key advantages of using PVC butterfly valves is their inherent resistance to corrosive substances, which is further validated by studies indicating a rising need for non-metallic valves in industries handling aggressive chemicals. As industries strive for sustainable practices, the lightweight nature of PVC butterfly valves not only simplifies installation and maintenance but also reduces overall energy consumption in transport and operation. Additionally, the cost-effectiveness and longevity of these valves, supported by reports from industry experts, underscore their position as a crucial component in modern industrial systems. As we delve into the top benefits of using PVC butterfly valves, it is essential to understand how they contribute to the efficiency and sustainability goals of contemporary industrial applications.

PVC butterfly valves are increasingly recognized for their advantages in industrial settings due to their lightweight structure, cost-effectiveness, and exceptional chemical resistance. In chemical processing industries, for instance, PVC butterfly valves are preferred for their ability to handle aggressive chemicals without risk of corrosion or degradation, leading to lower maintenance costs and enhanced durability. According to a recent industry report by the Global Valves Market Analysis, PVC valves, particularly in the butterfly category, are projected to capture a significant market share, highlighting the growing confidence in their application within various sectors such as water treatment, food processing, and pharmaceuticals.

The versatility of PVC butterfly valves is evident in their performance across diverse temperature ranges and pressures. A report from the Chemical Engineering Magazine notes that the operational capacity of PVC butterfly valves can range widely, often rated up to 150 psi, making them suitable for both low and moderate pressure systems. This flexibility allows industries to streamline operations while ensuring reliable performance. Additionally, the ease of installation and operation further accentuates their utility, providing industries with improved efficiency in processes where flow regulation and isolation are critical. Thus, PVC butterfly valves offer not just practical benefits but also align with the industry's push towards adopting sustainable and low-maintenance solutions.

PVC (Polyvinyl Chloride) is a material that brings numerous advantages to the construction of butterfly valves used in industrial applications. One of the most significant benefits of PVC is its outstanding resistance to corrosion. Unlike metal valves that can deteriorate over time due to exposure to various chemicals, PVC valves maintain their integrity against most corrosive substances, making them a reliable choice for handling aggressive fluids. This property not only extends the lifespan of the valves but also reduces maintenance costs, which can be substantial in industrial settings.

Another key advantage of using PVC in valve construction is its lightweight nature. PVC valves are significantly lighter than their metal counterparts, which simplifies the installation process and reduces the overall load on piping systems. This characteristic is particularly beneficial in applications where space and weight constraints are critical. Additionally, PVC can be easily molded into complex shapes and designs, allowing for greater flexibility in valve engineering and customization. This adaptability can lead to improved performance tailored to specific operational requirements, further enhancing the efficiency of industrial processes.

| Benefit | Description |

|---|---|

| Corrosion Resistance | PVC is inherently resistant to a wide range of corrosive chemicals, making it ideal for challenging environments. |

| Lightweight Construction | PVC valves are significantly lighter than metal alternatives, facilitating easier handling and installation. |

| Cost-Effective | PVC materials are generally less expensive than metals, providing a cost-effective solution for industrial applications. |

| Low Maintenance | Due to their durability and resistance to wear, PVC butterfly valves require less frequent maintenance. |

| High Flow Capacity | The design of butterfly valves allows for a wide flow range and low pressure drop, optimizing system performance. |

| Easy Operation | These valves can be easily operated manually or with actuators, allowing for simple integration into control systems. |

| Versatile Applications | PVC butterfly valves are suitable for a variety of applications, including water treatment, chemical processing, and HVAC systems. |

| Temperature Resistance | PVC can withstand a range of environmental temperatures, making it effective in diverse operating conditions. |

| Non-Toxic Material | PVC is non-toxic and safe for use in potable water systems, thereby enhancing health safety in applications. |

| Easy Installation | The lightweight nature of PVC simplifies the installation process, reducing labor and project time. |

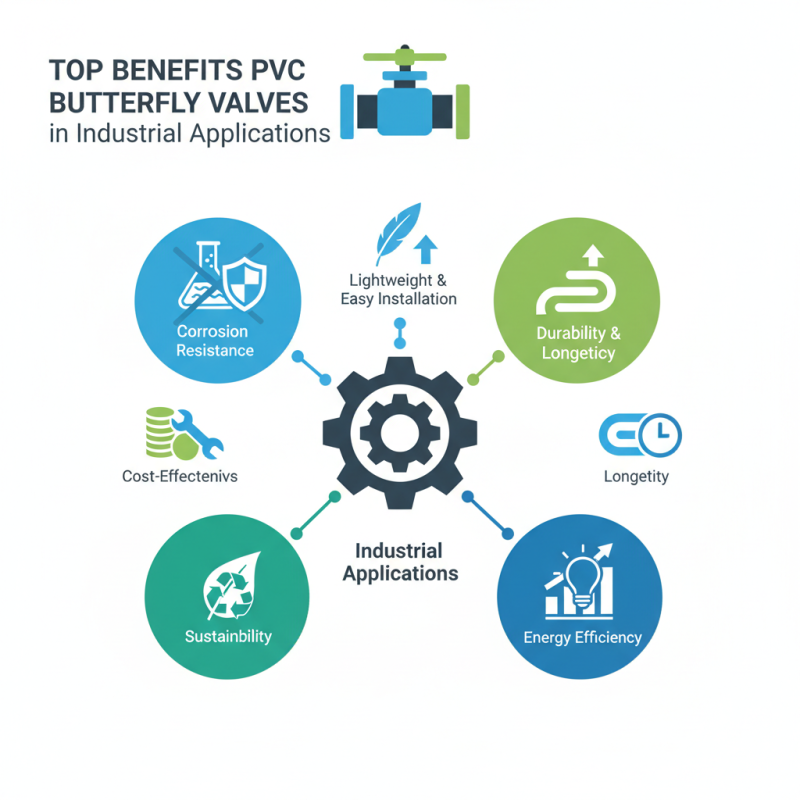

PVC butterfly valves have emerged as a preferred choice in various industrial applications due to their operational efficiency enhancements. One of the key advantages of using these valves lies in their lightweight design, which significantly reduces the energy required for installation and operation. According to a report by Research and Markets, the demand for lightweight and corrosion-resistant materials in industrial settings is expected to rise by approximately 5% annually through 2027. This trend highlights the growing importance of PVC butterfly valves, which not only facilitate easier handling but also reduce stress on piping systems.

In addition to their lightweight nature, PVC butterfly valves boast superior flow control capabilities. Their quarter-turn operation provides rapid opening and closing, leading to reduced cycle times and improved process efficiency. A study conducted by the International Journal of Engineering and Technology found that implementing PVC butterfly valves can lead to efficiency gains of up to 30% in fluid handling systems. This enhanced flow management is particularly beneficial in applications requiring precise regulation of liquids, ultimately contributing to increased productivity and lower operational costs across industries. With ongoing advancements in PVC material technology, the operational benefits of these valves are likely to expand further, solidifying their role in modern industrial infrastructure.

PVC butterfly valves offer significant cost-effectiveness in long-term industrial applications. One of the primary advantages of these valves is their

durability and resistance to corrosion, which translates to reduced maintenance costs over their lifetime. Unlike metal valves, which can be susceptible to rust and degradation, PVC butterfly valves maintain their integrity under various environmental conditions, including exposure to harsh chemicals. This durability ensures that industries can minimize replacement frequency, leading to substantial savings over time.

Moreover, the lightweight nature of PVC butterfly valves simplifies installation processes, reducing labor costs associated with valve handling and installation. Lower energy requirements for operations further enhance their cost effectiveness; these valves typically require less power to operate compared to heavier alternatives. As industries aim to optimize their operational expenses, choosing PVC butterfly valves can provide an

efficient solution on both initial investments and long-term operational costs, making them a wise choice for various industrial applications.

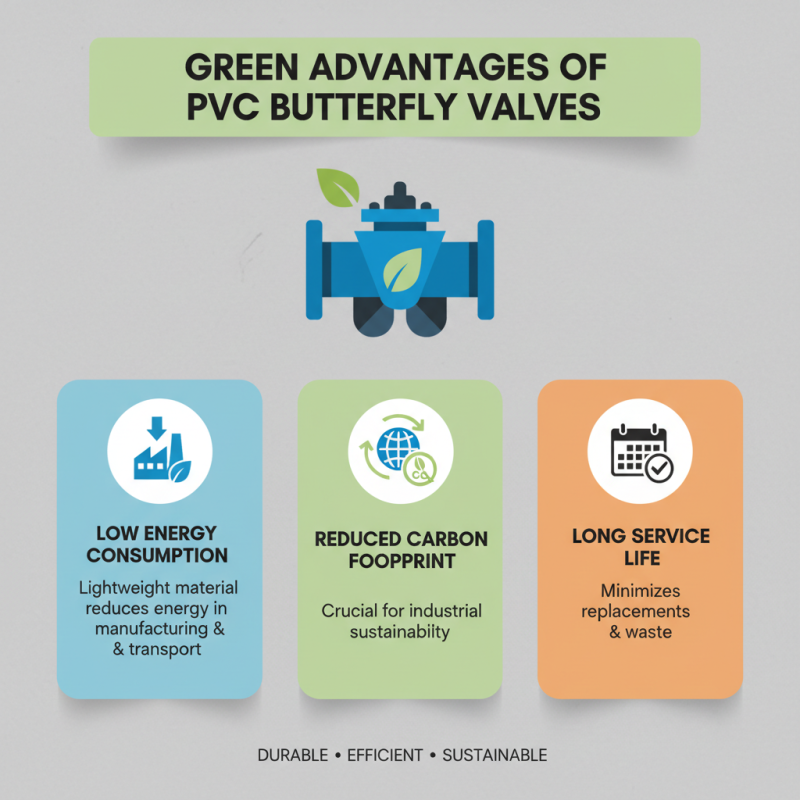

The use of PVC butterfly valves offers significant advantages in terms of environmental impact and sustainability. PVC, being a lightweight and durable material, contributes to lower energy consumption during manufacturing and transportation. This is particularly crucial in industrial applications where reducing the carbon footprint is becoming increasingly important. Additionally, PVC butterfly valves have a long service life, significantly minimizing the need for replacements and the associated waste.

When considering the environmental sustainability of PVC butterfly valves, it's essential to recognize their resistance to corrosion and chemical degradation. This feature not only extends their usability in various industrial settings but also reduces the potential for leakage, which can lead to environmental contamination. Moreover, the recyclability of PVC means that at the end of their life cycle, these valves can be repurposed, further lowering their ecological impact.

**Tips for Implementation:** When selecting PVC butterfly valves for industrial applications, ensure they meet the required environmental standards for your specific sector. Regular maintenance checks can prolong their lifespan and enhance their performance, ultimately leading to decreased waste generation. Additionally, consider working with suppliers who prioritize sustainable manufacturing practices to further support eco-friendly initiatives in your operations.