Butterfly valve actuators play a vital role in the operation of various industrial systems, facilitating the effective control of fluid flow through valves. Understanding the different types of butterfly valve actuators, alongside their benefits and applications, is crucial for engineers and facility managers to optimize system performance. These actuators vary in design, including pneumatic, electric, and hydraulic variations, each offering unique advantages suited to specific operational demands.

The benefits of utilizing butterfly valve actuators include not only enhanced efficiency and reliability but also improved safety and maintenance procedures. Their compact design allows for space-saving installations, making them ideal for both large and small-scale systems. Furthermore, the versatility of these actuators ensures their applicability across various industries, from water treatment facilities to manufacturing plants, highlighting their importance in modern automation processes.

As industries increasingly prioritize automation and efficiency, gaining a comprehensive understanding of butterfly valve actuators becomes paramount. This knowledge equips operators with the necessary insights to select the right actuator type for their specific needs, ultimately leading to more streamlined operations and reduced downtime. By delving into the components, functionality, and applications of butterfly valve actuators, we can appreciate their critical role in enhancing system performance across diverse sectors.

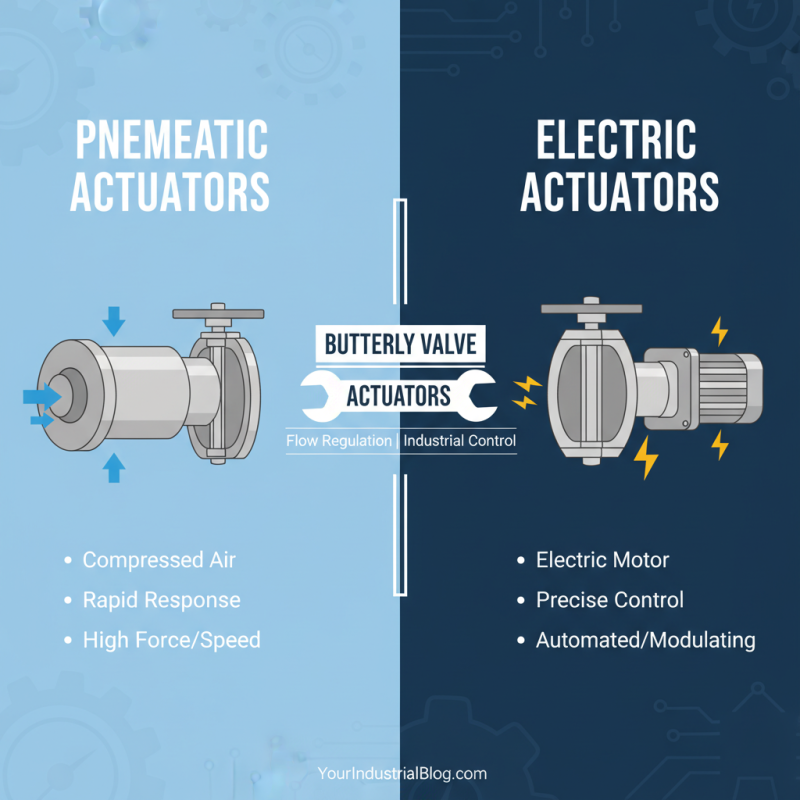

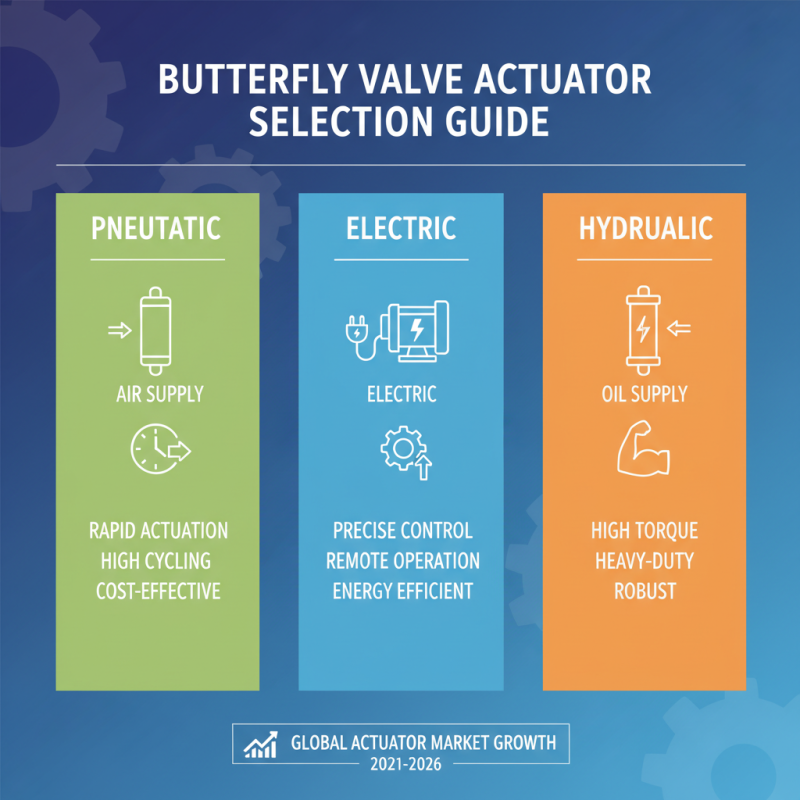

Butterfly valve actuators are essential components in many industrial applications, providing precise control over flow regulation in a variety of systems. The two primary types of butterfly valve actuators are pneumatic actuators and electric actuators, each offering distinct advantages suited to different operational environments. Pneumatic actuators use compressed air to actuate the valve, making them ideal for quick operations and environments where rapid response times are crucial. They excel in high-speed applications and can provide significant force, making them suitable for larger valves.

On the other hand, electric actuators utilize electrical energy to operate the valve, offering benefits such as easy integration with automation systems and more straightforward control mechanisms. These actuators can be ideal for applications that require precise positioning and control, as they often come equipped with feedback mechanisms. The choice between pneumatic and electric actuators typically depends on factors such as the specific application requirements, environmental conditions, and the level of control needed. Understanding these types enhances decision-making in selecting the appropriate actuator for enhancing efficiency and functionality in various processes.

Butterfly valve actuators play a critical role in various industries, offering numerous advantages that enhance operational efficiency. One of the key benefits of these actuators is their simplicity and compact design, allowing for easy installation and maintenance in tight spaces. According to a recent report by Research and Markets, the global butterfly valve market is expected to reach $8.2 billion by 2027, highlighting the increasing demand for efficient flow control solutions across sectors such as oil and gas, water treatment, and power generation.

In addition to their cost-effectiveness, butterfly valve actuators provide a high degree of automation. This is particularly advantageous in modern industries where precision and remote operations are paramount. Automation can reduce labor costs and minimize the risk of human error, aiding in compliance with safety standards. A study by Frost & Sullivan indicates that the automation of valve systems can improve process efficiency by up to 20%, making these actuators a pivotal technology in the industrial landscape.

Tips: When selecting a butterfly valve actuator, consider the specific operational requirements, including the size of the valve, the medium being controlled, and environmental conditions. Additionally, regular maintenance can further enhance the actuator's longevity and performance, ensuring reliable operation in critical applications. Implementing a proactive maintenance schedule can mitigate potential downtime, optimizing productivity in the long term.

Butterfly valve actuators play a crucial role in various sectors, thanks to their efficiency and versatility. In the water and wastewater treatment industry, these actuators are commonly used for controlling the flow of water and other fluids. Their quick response times allow for precise regulation of water levels, which is essential for maintaining proper treatment processes. The compact design of butterfly valves also makes them ideal for installation in tight spaces, contributing to streamlined plant operations.

In the HVAC (Heating, Ventilation, and Air Conditioning) sector, butterfly valve actuators are employed to manage airflow effectively. They enable the modulation of air volume in duct systems, providing energy efficiency and comfort in commercial and residential buildings. Additionally, in the chemical processing industry, these actuators are favored for their ability to handle corrosive substances while maintaining reliable performance. Their simplicity in design means fewer parts to maintain, further enhancing their appeal for applications where downtime must be minimized. Overall, the adaptability of butterfly valve actuators across diverse sectors underscores their importance in modern industrial systems.

| Type | Benefits | Common Applications | Sector |

|---|---|---|---|

| Electric Actuator | Fast response, precise control | Water Treatment | Environmental |

| Pneumatic Actuator | High speed, capable of high torque | Oil and Gas | Energy |

| Hydraulic Actuator | Strong force, suitable for large valves | Power Generation | Industrial |

| Manual Actuator | Cost-effective, simple operation | HVAC Systems | Building Services |

When selecting a butterfly valve actuator, several critical factors must be taken into account to ensure optimal performance and reliability. One of the foremost considerations is the actuator type, which can be pneumatic, electric, or hydraulic. Each type presents its unique advantages; for instance, pneumatic actuators are often preferred in applications requiring rapid actuation and high cycling rates. According to a report by MarketsandMarkets, the global actuator market is projected to grow from $XX billion in 2021 to $XX billion by 2026, highlighting the increasing importance of selecting the right actuator for specific applications.

Another crucial factor is the actuator's torque output, which must align with the specific operational demands of the butterfly valve. Proper torque ensures that the valve can efficiently open and close against the system pressures it encounters. The American Society of Mechanical Engineers (ASME) suggests that understanding the valve's flow characteristics and system pressure will aid in calculating the necessary torque, typically ranging from 20 to 200 Nm for most industrial applications. Additionally, environmental factors such as temperature, humidity, and exposure to corrosive elements must also be evaluated, as they can significantly influence actuator performance and lifespan.

Finally, control mechanisms and integration with existing systems are essential aspects to consider. The ability to implement automated controls can enhance operational efficiency, allowing for real-time monitoring and adjustments. A study from the International Society of Automation (ISA) indicates that integrating smart technologies with actuators can improve valve performance by up to 30%, showcasing the value of technology in contemporary valve actuation systems. By carefully assessing these factors, users can ensure they select the most suitable butterfly valve actuator for their needs.

Maintaining butterfly valve actuators is essential to ensure proper functionality and longevity in various applications. Regular inspection is crucial; operators should frequently check for any signs of wear or damage, particularly in the actuator's gears and seals. Lubricating moving parts according to the manufacturer’s guidelines helps reduce friction and prevent premature wear. Additionally, ensuring that the actuator is appropriately aligned with the valve can prevent operational issues that may arise from misalignment.

In terms of troubleshooting, common issues such as slow operation or complete failure can often be traced back to electrical or air supply problems. It’s important to verify that the actuator has the appropriate power supply and connections. In cases where the control signal is weak or interrupted, recalibrating the automation components may be necessary. Operators should also examine the actuator for any blockages or mechanical failures that might impede its movement. Keeping documentation of these checks and addressing issues promptly can significantly extend the actuator's operational life and improve overall system reliability.