In the ever-evolving landscape of industrial applications, the choice of components plays a crucial role in operational efficiency and safety. Among these components, the air actuated ball valve has emerged as a staple for many industries, owing to its reliability and precise control capabilities. According to a recent market report, the global valve market is projected to reach $100 billion by 2026, with air actuated ball valves accounting for a significant share due to their wide applicability in sectors such as oil and gas, water treatment, and chemical processing. The demand for automation and high-performance solutions further underscores the importance of selecting the right air actuated ball valve to meet specific operational needs. This guide aims to provide insights into the key factors to consider when selecting an air actuated ball valve, ensuring that industrial operations can maximize efficiency and productivity while minimizing costs and downtime.

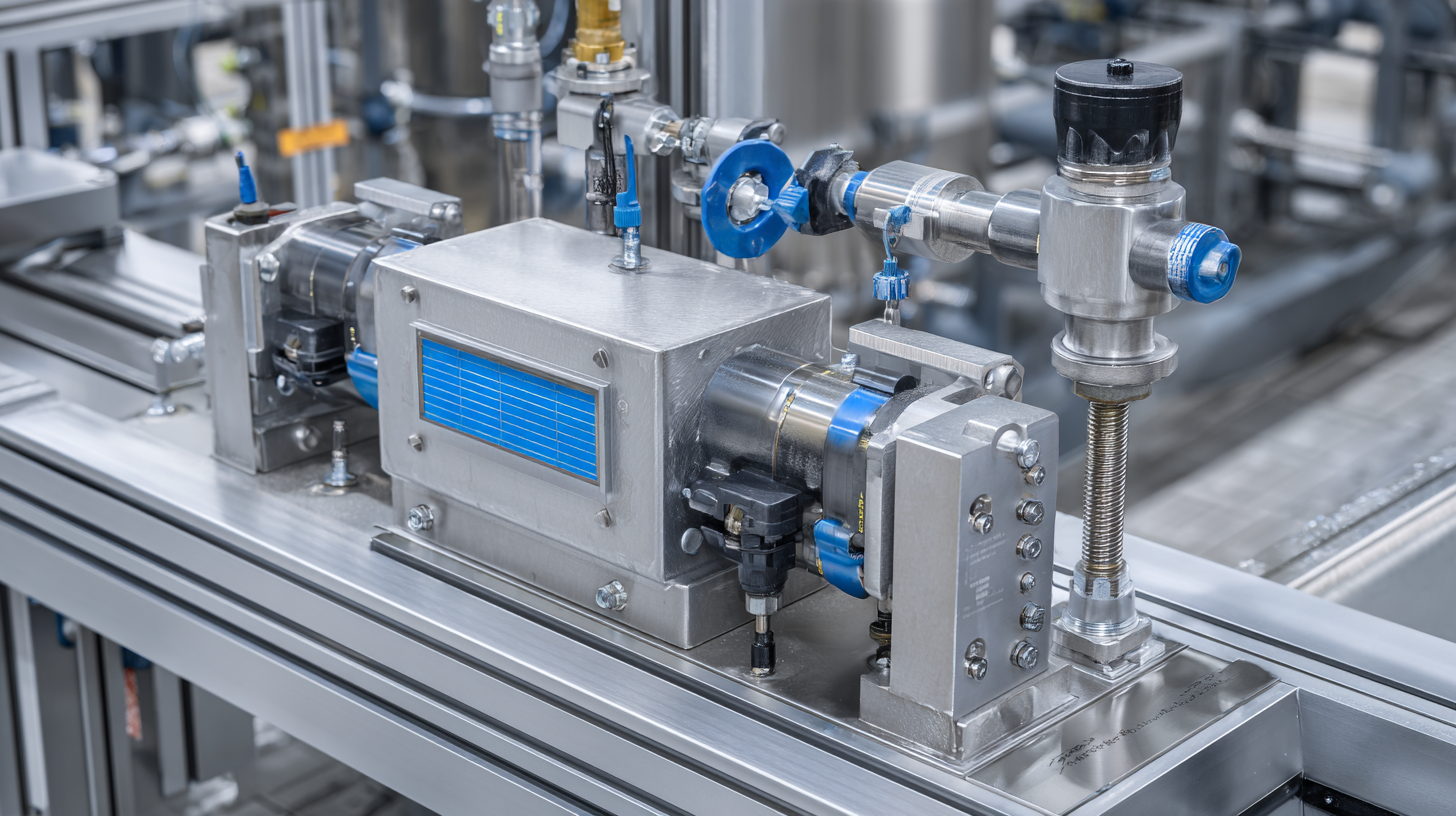

Air actuated ball valves are essential components in many industrial applications, offering a combination of efficiency, reliability, and precision. These valves utilize compressed air to operate, providing quick response times and the ability to control fluid flow in both large and small systems. One of the main features of air actuated ball valves is their ability to operate automatically, allowing for seamless integration into automated processes. This automation not only enhances productivity but also reduces the risk of human error.

In terms of benefits, air actuated ball valves are designed to handle a wide range of fluids, including corrosive and high-viscosity materials. Their robust construction allows them to withstand high pressures and temperatures, making them suitable for demanding environments. Additionally, many models come with fail-safe options, ensuring that the valve returns to a safe position in the event of an air failure. This inherent safety feature is crucial for industries that require strict compliance with safety regulations and operational reliability. Understanding these features and benefits will guide you in selecting the right air actuated ball valve tailored to your specific industrial needs, ensuring optimal performance and efficiency in your systems.

When selecting air actuated ball valves for industrial applications, several key considerations must guide your choice, especially in environments with high pressure. High-pressure valves are critical as they are specifically designed to handle pressures exceeding the standard limits of regular valves. According to a report from a leading industrial association, improper valve selection can lead to failures, which are costly and can pose safety hazards. It is essential to assess the valve's pressure rating and ensure it aligns with the pressures encountered in your specific application.

Another significant factor is the environment in which the valve will operate. For instance, if the application involves robotics, speed, force, and weight become crucial considerations. Pneumatics have proven to be a reliable technology in such scenarios, delivering fast response times and precise control. Industry studies indicate that pneumatic systems can offer operational efficiencies of over 30% compared to other methods, making them an ideal choice for dynamic environments. Thus, evaluating the compatibility of air actuated ball valves with your process requirements, alongside consideration of material and actuator specifications, will ensure optimal performance and longevity of the system.

When selecting an air actuated ball valve for industrial applications, understanding sizing and pressure ratings is crucial for optimal performance. Size directly influences the flow rate and pressure drop across the valve, which can significantly impact system efficiency. According to a report by the American Society of Mechanical Engineers (ASME), a correctly sized valve can improve flow efficiency by up to 15%, minimizing energy consumption and operational costs. It is essential to match the valve size to the diameter of the piping system to prevent issues such as cavitation or sluggish response times.

Pressure ratings are equally important when choosing a ball valve. Most industrial valves are rated according to the ANSI/ASME B16.34 standard, which categorizes valves based on pressure-temperature ratings. For instance, a valve rated at 150 psig is suitable for applications with lower pressure requirements, while a 300 psig valve is ideal for high-pressure situations. The Fluid Control Institute notes that using a valve with an appropriate pressure rating can prevent premature failure and enhance safety in high-stakes environments, where pressure fluctuations can lead to catastrophic failures. Therefore, meticulous evaluation of both sizing and pressure ratings ensures that the selected air actuated ball valve will perform reliably under varying conditions.

When selecting an air actuated ball valve for industrial applications, assessing material compatibility and environmental factors is crucial. According to a report by the International Society of Automation, improper material selection can lead to significant operational inefficiencies, resulting in costs exceeding $1 million annually for large facilities. Therefore, choosing a valve made from materials that can withstand specific chemical exposures is essential. For instance, stainless steel is commonly used for its corrosion resistance, while PTFE-lined valves may be required in applications involving aggressive chemicals.

Environmental factors also play a critical role in valve selection. Research from the American Society of Mechanical Engineers highlights that valves exposed to extreme temperatures or corrosive environments may require specialized coatings or materials to ensure longevity and efficiency. Additionally, understanding the operational environment, such as the presence of moisture, airborne contaminants, and temperature fluctuations, can guide manufacturers in choosing the right ball valve. By carefully evaluating these factors, industries can prevent failures and enhance the reliability of their fluid control systems, ultimately yielding safer and more efficient operations.

| Valve Type | Material | Temperature Range (°C) | Pressure Rating (bar) | Compatibility | Applications |

|---|---|---|---|---|---|

| Standard Ball Valve | Stainless Steel | -20 to 150 | 16 | Water, Air | Oil & Gas, Water Treatment |

| High Temperature Ball Valve | Inconel | -50 to 200 | 20 | Steam, Hot Oil | Chemical Processing |

| Cryogenic Ball Valve | Brass | -196 to 50 | 10 | Liquid Nitrogen, LNG | Cryogenics, Aerospace |

| Plastic Ball Valve | PVC | -10 to 60 | 6 | Acids, Bases | Agriculture, Water Treatment |

When incorporating air actuated ball valves into industrial systems, understanding their maintenance practices is crucial for maximizing performance and longevity.

Regular inspections are essential to identify signs of wear or damage. It’s recommended to check seals and actuator components for any leaks or irregularities. Additionally, keeping the valve clean from debris and buildup ensures smooth operation and reduces the risk of malfunction. Adopting a routine lubrication schedule for moving parts can further enhance reliability, particularly in environments with fluctuating temperatures or exposure to corrosive materials.

Lifespan expectations for air actuated ball valves can vary significantly based on usage, environmental conditions, and maintenance diligence. Typically, high-quality valves can last anywhere from 5 to 15 years if maintained properly. However, factors like heavy-duty cycles, harsh chemical exposure, or inadequate maintenance can diminish their lifespan. Implementing a proactive maintenance strategy not only extends the operational life of these valves but also contributes to overall system efficiency, reducing the frequency of costly replacements and downtime.