When it comes to controlling fluid flow in various industrial applications, the selection of the appropriate butterfly valve actuator is critical. Butterfly valves, known for their compact design and efficiency, are widely used in pipelines to regulate the flow of liquids and gases. The actuator plays a vital role in determining how effectively these valves open or close, impacting the overall performance of the system. Therefore, understanding the different types of butterfly valve actuators and their respective functionalities is essential for engineers and decision-makers.

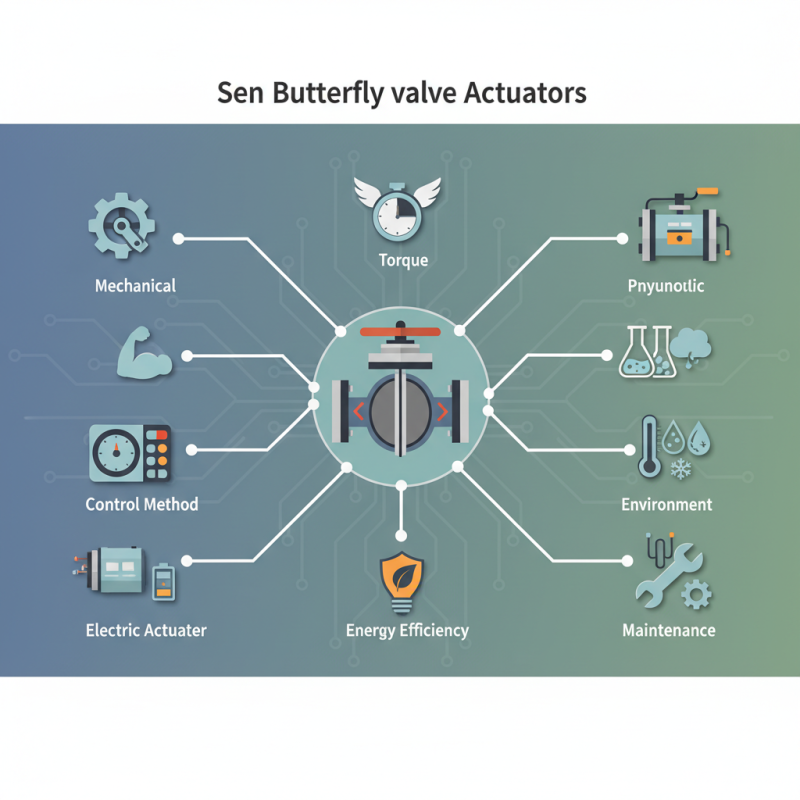

Choosing the right butterfly valve actuator involves several considerations, including the specific requirements of the application, the medium being transported, and the environment in which the actuator will operate. Factors such as torque, speed, and control method can greatly influence the actuator's performance. Additionally, aspects such as energy efficiency, reliability, and maintenance requirements are crucial in ensuring long-term operation without unforeseen downtimes. As we delve into the intricacies of selecting the suitable actuator, we will explore the critical parameters that guide this decision-making process, helping to ensure that the chosen solution aligns seamlessly with both operational needs and strategic goals.

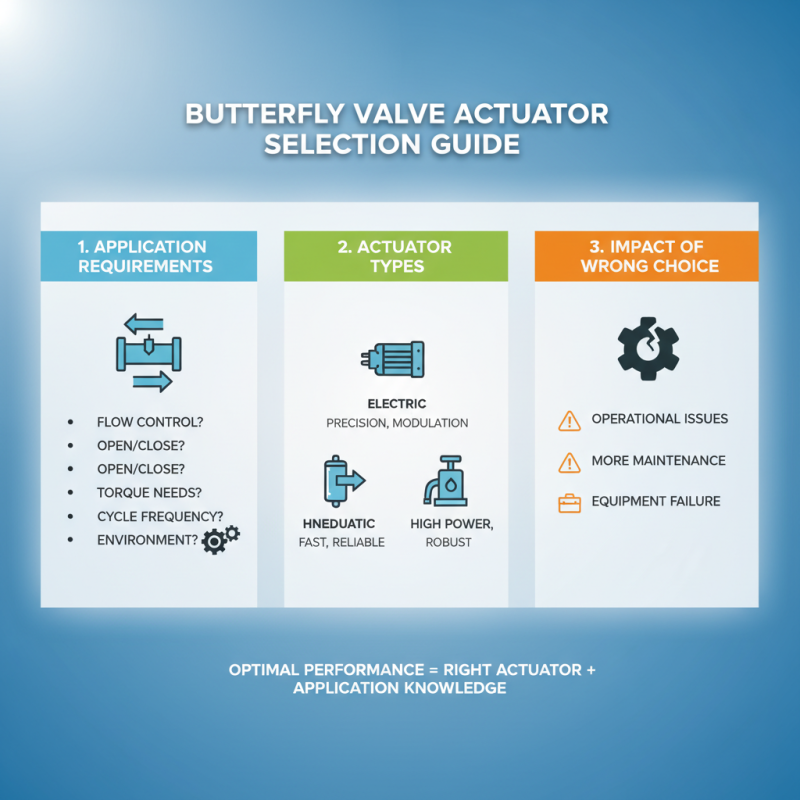

Selecting the right actuator for butterfly valves is crucial in ensuring optimal performance and longevity of your system. The actuator is responsible for opening and closing the valve, directly impacting flow control, efficiency, and reliability in various applications. An improper choice can lead to operational issues, increased maintenance costs, and potential equipment failure. Therefore, understanding the specific requirements of your application is essential for making an informed decision.

When choosing an actuator, consider factors such as the type of control method, required torque, and environmental conditions. Electric actuators offer precise control and are ideal for applications where a reliable power source is available. On the other hand, pneumatic actuators provide rapid operation and are advantageous in situations where quick response times are necessary. Additionally, assess the actuator's compatibility with the valve size and type, as mismatches can result in inefficient operation.

**Tips:**

1. Always consult the manufacturer's guidelines to ensure compatibility with your specific butterfly valve model.

2. Evaluate the ambient conditions where the actuator will operate; extreme temperatures or corrosive environments may require specialized actuators.

3. Consider the maintenance requirements of the actuator; some designs offer easy disassembly and repair, which can save costs in the long run.

When selecting a butterfly valve actuator, understanding the different types of actuators—electric, pneumatic, and hydraulic—is crucial for ensuring optimal performance in your application. Electric actuators are renowned for their precision and ease of integration with automated systems. They require minimal maintenance, as they have fewer moving parts and can be easily controlled with digital signals. This makes them a suitable choice for applications where reliable operation and remote accessibility are paramount.

On the other hand, pneumatic actuators leverage compressed air to provide rapid opening and closing of the valve. They are favored in applications that demand high-speed operation and are capable of providing substantial torque, making them ideal for larger valves. However, they require an air supply and might need more maintenance compared to their electric counterparts. Lastly, hydraulic actuators are designed for high torque applications, utilizing hydraulic fluid to generate force. They excel in environments with heavy-duty demands, such as those found in industrial settings. While they can be more complex in terms of setup and maintenance, their capability to handle larger loads makes them indispensable in certain applications.

When selecting a butterfly valve actuator, it's essential to focus on key specifications that ensure optimal performance for your specific application. Torque is one of the primary factors to evaluate. It refers to the rotational force produced by the actuator, which must be sufficient to open and close the valve under varying pressure conditions. Assessing the required torque involves considering the size of the valve, the media being handled, and the system pressure. A mismatch in torque requirements can lead to operational inefficiencies, potential damage, or even complete failure of the valve.

Another critical specification is the speed of the actuator. The speed at which the valve operates can significantly impact the overall efficiency of the system. A faster actuator can be beneficial in applications requiring quick responses or frequent adjustments, while slower speeds may be appropriate for systems where gradual control is essential. It's important to align the actuator speed with the operational needs of the process, ensuring that it meets control requirements without compromising safety or reliability.

Lastly, the duty cycle should not be overlooked. Duty cycle indicates how long the actuator can operate continuously without overheating or requiring rest periods. This is particularly important in applications with high-frequency cycles or prolonged continuous operation. Understanding the duty cycle will help in selecting an actuator that can maintain performance standards over time, thus ensuring the longevity and efficiency of the butterfly valve system.

When selecting the right butterfly valve actuator for a specific application, it is crucial to focus on the operational requirements and environmental conditions the system will face. Each application has unique demands based on factors such as pressure, temperature, and fluid characteristics. For low-pressure systems, a simpler actuator may suffice, while high-pressure applications may require more robust designs with fail-safe features to ensure safety and reliability. Understanding these operational parameters allows engineers to match the actuator type—whether pneumatic, electric, or hydraulic—to the specific needs of the system.

Additionally, consideration of the environment in which the actuator will operate is essential. Factors such as ambient temperature, exposure to corrosive substances, and the potential for dust or moisture ingress must all influence the selection process. For outdoor applications, selecting actuators with appropriate weather protection ratings can prevent premature failure and ensure longevity. By aligning actuator features with both the operational requirements and environmental challenges, you can enhance the effectiveness of the butterfly valve within the overall system, thereby improving efficiency and reducing maintenance costs over time.

| Application | Actuator Type | Power Source | Torque Requirement (Nm) | Response Time (Sec) | Control Signal Type |

|---|---|---|---|---|---|

| Water Treatment | Electric | AC Power | 50 | 2 | 4-20 mA |

| HVAC Systems | Pneumatic | Compressed Air | 75 | 1.5 | 0-10 V |

| Oil and Gas | Manual | N/A | 100 | N/A | N/A |

| Pharmaceuticals | Electric | DC Power | 30 | 3 | Modbus |

| Food Processing | Hydraulic | Hydraulic Fluid | 90 | 2.5 | Pneumatic Signal |

When selecting a butterfly valve actuator, understanding common industry practices and standards is essential for ensuring reliable performance across various applications. Many industries adhere to specific operational guidelines, which are shaped by factors such as environmental conditions and regulatory requirements. Familiarizing yourself with these standards can help streamline the selection process, resulting in an actuator that not only meets operational demands but also aligns with industry norms for safety and efficiency.

Tip: Always consult relevant industry standards such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO) to ensure compliance. Assess the actuator's compatibility with the butterfly valve's specifications, including size, torque requirements, and voltage ratings, to avoid costly modifications after installation.

Another critical aspect is understanding the actuator's control features. Many industries prefer actuators with advanced control systems that provide real-time feedback and remote operation capabilities. This not only enhances operational flexibility but also promotes proactive maintenance strategies.

Tip: Involve cross-disciplinary team members when evaluating actuator options; their insights can illuminate vital considerations based on practical experience, which may influence your choice. This collaborative approach can lead to a more informed selection, ultimately yielding greater satisfaction with the actuator's performance in real-world applications.