Choosing the right high pressure ball valve for your applications can be a daunting task, particularly given the wide range of options available in the market. High pressure ball valves are essential components in various industrial processes, playing a critical role in controlling the flow of fluids under high-pressure conditions. When selecting the appropriate valve, one must consider several factors, including material compatibility, pressure rating, and the specific requirements of the application.

In this guide, we will explore the key aspects to consider when choosing a high pressure ball valve, ensuring that you make informed decisions that enhance the efficiency and safety of your operations. As industries evolve and technologies advance, understanding the nuances of high pressure ball valves has become increasingly important. From the basic design principles to advanced features, this article aims to provide a comprehensive overview that will help you navigate the complexities of valve selection.

Whether you are in the oil and gas sector, chemical processing, or any other field that requires reliable flow control, the right high pressure ball valve can significantly impact your system's performance. Join us as we highlight the top ten considerations for selecting a high pressure ball valve in 2025, ensuring that your choices align with industry standards and operational needs.

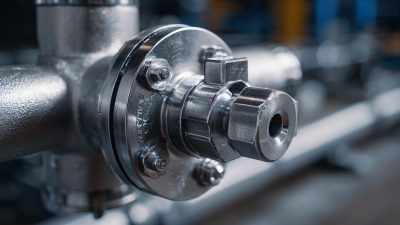

When selecting a high pressure ball valve for your applications, it is crucial to understand the various types available. The primary classifications include floating ball valves and trunnion-mounted ball valves. Floating ball valves are designed to allow the ball to float, and they utilize the pressure from the pipeline to seal the valve. This design is particularly effective in smaller sizes and moderate pressures, offering excellent performance in services where a tight seal is required.

On the other hand, trunnion-mounted ball valves feature a ball that is fixed at the top and bottom, providing additional stability under high pressure and larger sizes. These valves are well-suited for applications that demand higher flow rates and consist of more robust constructions, making them ideal for heavy-duty industrial situations. Understanding these differences is fundamental in selecting the right valve type that aligns with your pressure requirements, fluid characteristics, and operational conditions. By assessing the specific needs of your application, you can ensure optimal performance and reliability.

When choosing the right high-pressure ball valve for your applications, selecting the appropriate valve material is crucial for ensuring reliability and performance. One significant trend in valve material selection is the shift towards titanium castings, particularly within naval applications, due to their superior corrosion resistance in seawater environments. This choice not only enhances the durability of the valves but also proves to be cost-effective over the long term, highlighting the importance of material properties in high-pressure and corrosive settings.

In addition to titanium, other materials such as polyurethane are gaining attention in specialized applications, such as heart valve replacements. The advancements in polymer chemistry have demonstrated the potential of polyurethane to translate into clinical benefits, showcasing its versatility as a valve material. As industries evolve and push for more efficient and reliable solutions, understanding the properties and characteristics of valve materials will be essential in making informed decisions that align with operational demands and environmental considerations.

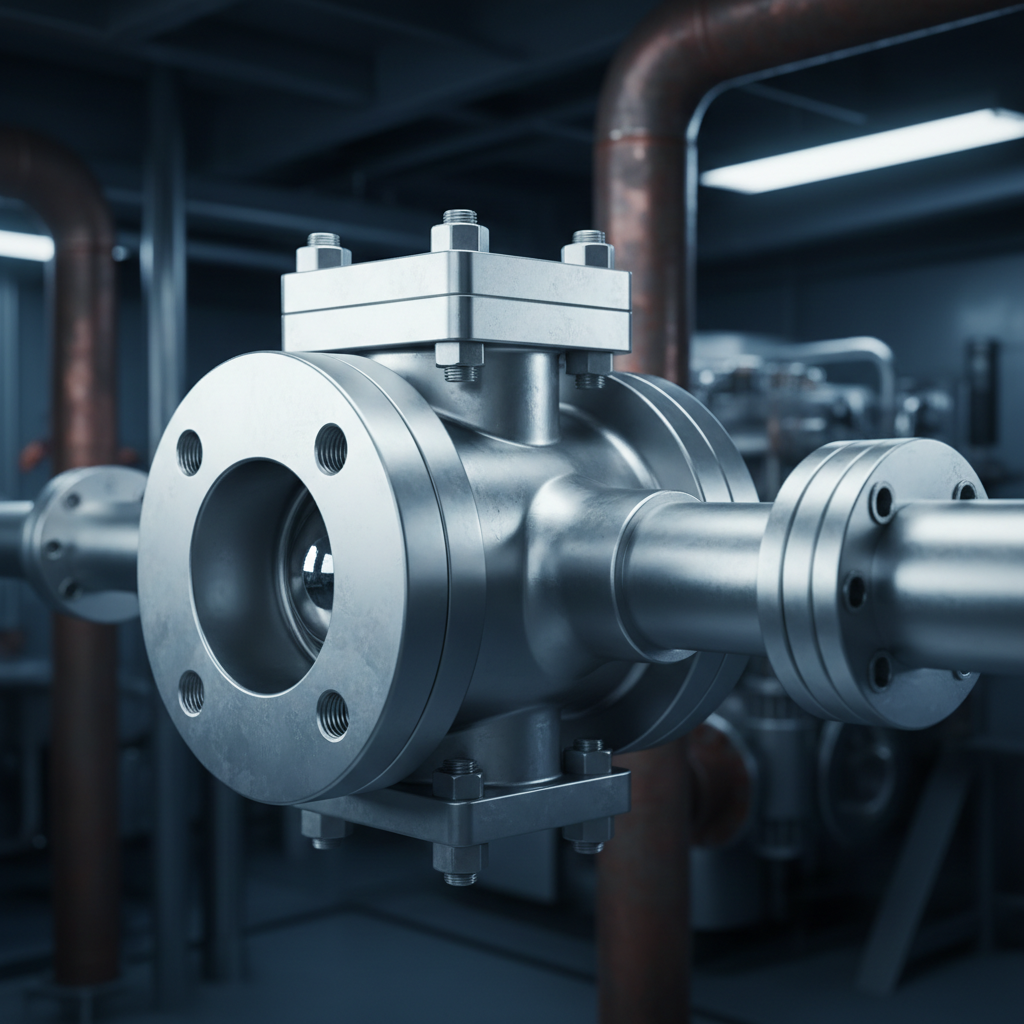

When selecting a high pressure ball valve for specific applications, understanding the pressure and temperature ratings is crucial. These ratings provide essential information about the valve's capacity to handle varying conditions without compromising performance or safety. The pressure rating indicates the maximum pressure the valve can withstand in operation, which is vital for maintaining system integrity. It is important to choose a valve that meets or exceeds the pressure requirements of your application to prevent leaks or failures.

Similarly, temperature ratings indicate the range of temperatures the valve can operate within safely. High temperature conditions can affect the material properties of the valve, potentially leading to deformation or failure. When evaluating valves, it's imperative to consider both the maximum operating pressure and temperature, ensuring that the selected valve is compatible with the working environment. Additionally, pay attention to the materials used in the valve construction, as the right material selection can enhance durability and performance under extreme conditions. This comprehensive evaluation of pressure and temperature ratings can significantly impact the success of your application.

| Valve Size (inches) | Pressure Rating (PSI) | Temperature Rating (°F) | Body Material | End Connection Type |

|---|---|---|---|---|

| 1" | 6000 | -20 to 450 | 316 Stainless Steel | Flanged |

| 2" | 3000 | -20 to 400 | Carbon Steel | Screw |

| 3" | 1500 | -4 to 370 | PVC | Socket Weld |

| 4" | 1000 | 0 to 350 | Brass | Threaded |

| 6" | 600 | -40 to 300 | Cast Iron | Flanged |

When selecting a high-pressure ball valve, assessing valve size and port configuration is crucial for ensuring optimal performance in your application. The size of the valve not only influences the flow rate but also affects pressure drop and overall system efficiency. To determine the appropriate size, it’s essential to evaluate the specifications of your system, including the fluid type, temperature, and pressure conditions. A valve that is too small may restrict flow and increase the strain on the entire system, while one that is excessively large could result in a lack of control in the process.

Port configuration also plays a significant role in the functionality of the valve. Common configurations include full port and reduced port options, each offering different levels of flow capacity. A full port valve allows for maximum flow, making it ideal for applications where pressure loss must be minimized. Conversely, a reduced port valve may be suitable in situations where space is at a premium or where flow requirements are less stringent. By carefully considering both the valve size and port configuration, you can choose a high-pressure ball valve that meets your specific operational needs and maintains system integrity.

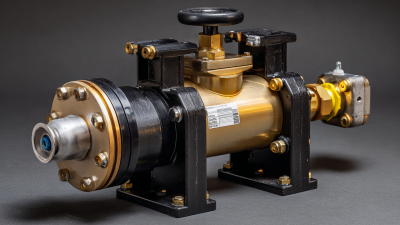

When selecting high pressure ball valves for your application, understanding the various actuation options is critical to achieving optimal performance. Actuators are essential components that facilitate the valve's opening and closing, and choosing the right one can significantly enhance efficiency in your processes. Today, intelligent electric actuators are leading the way in various industrial applications, providing greater control and reliability. These modern actuators not only improve operational efficiency but also offer ease of integration into existing systems.

Tips for selecting the right actuator: Include assessing the specific requirements of your application, such as the operating pressure, temperature, and the type of fluid being controlled. Consider whether you need a manual operation or an automated solution, as this impacts both your workflow and operational safety. Additionally, evaluate the actuator's compatibility with the valve type and its maintenance requirements to ensure long-term reliability and performance.

Keep an eye on evolving technologies as the industry advances. Innovations like zero-friction flow solutions are making waves, promising reduced downtime and heightened safety. This not only reflects a trend towards smarter, more efficient systems but also highlights the importance of staying updated with the latest products in the control valve market to make informed decisions that meet your operational goals.