Choosing the right pneumatic valve for your industrial applications is crucial for optimizing efficiency and ensuring safety in various processes. According to a recent report by the Industrial Automation Group, the global pneumatic valve market is projected to reach $5.7 billion by 2026, growing at a CAGR of 4.2%. This growth is driven by the increasing demand for automation across industries, including manufacturing, automotive, and food processing.

Choosing the right pneumatic valve for your industrial applications is crucial for optimizing efficiency and ensuring safety in various processes. According to a recent report by the Industrial Automation Group, the global pneumatic valve market is projected to reach $5.7 billion by 2026, growing at a CAGR of 4.2%. This growth is driven by the increasing demand for automation across industries, including manufacturing, automotive, and food processing.

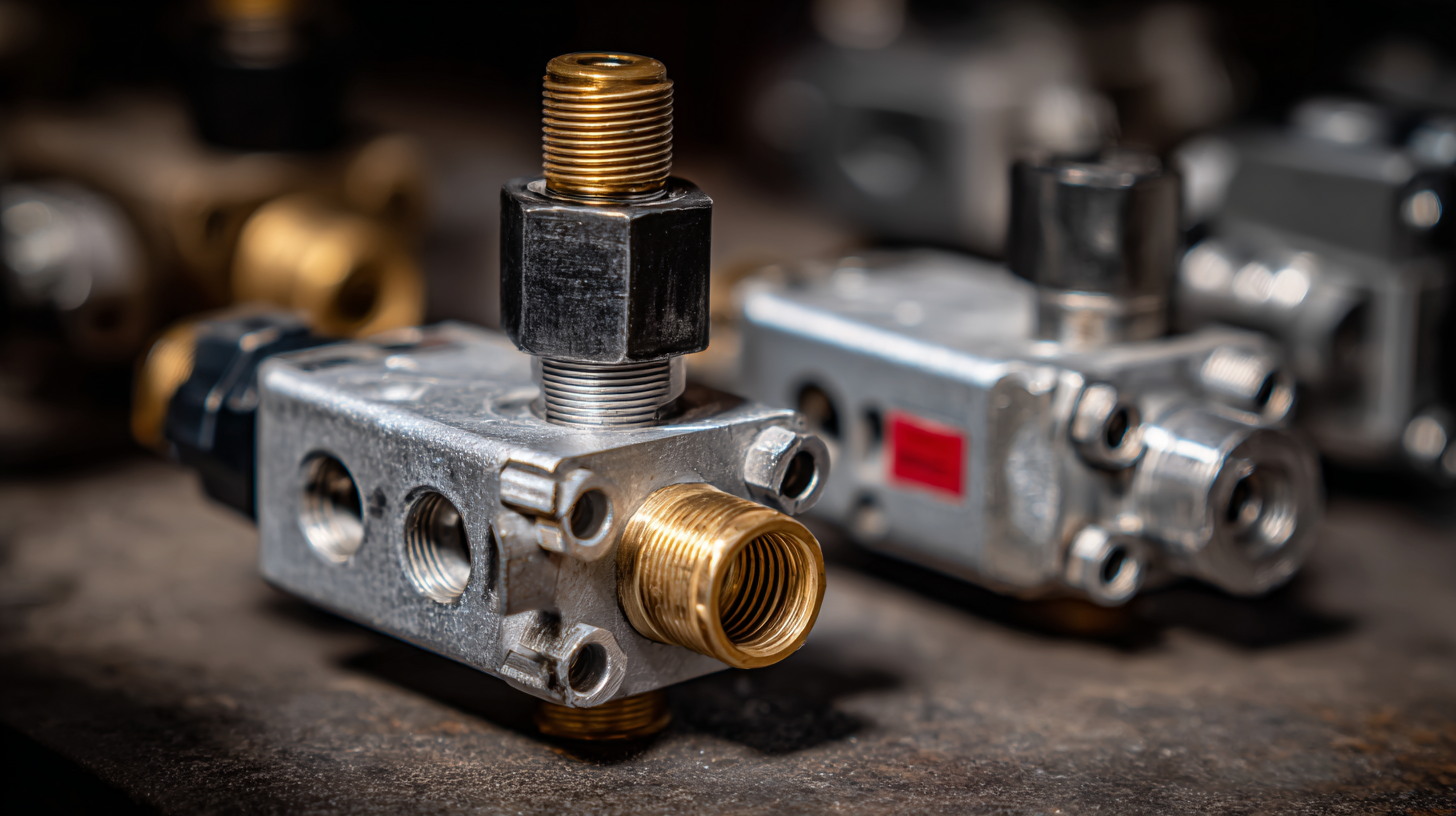

Pneumatic valves play a pivotal role in controlling the flow of air and fluids, thereby regulating machinery and processes. With a plethora of options available in terms of design, actuation methods, and materials, selecting the appropriate pneumatic valve can significantly impact operational productivity and maintenance costs.

In this tutorial, we will explore essential criteria for evaluating pneumatic valves, ensuring that you make an informed choice that meets the specific needs of your industrial applications.

When selecting a pneumatic valve for industrial applications, several key factors must be considered to ensure optimal functionality and efficiency. Firstly, the type of valve plays a crucial role; choosing between directional control, flow control, or pressure relief valves is essential based on the specific requirements of your system. Each valve type serves different purposes, and understanding your application’s needs will guide you towards the correct choice.

Another critical factor is the valve’s size and flow capacity. It's important to match the valve size with your system's flow requirements to prevent pressure drops or operational inefficiencies. Additionally, the material of the valve is significant; selecting corrosion-resistant materials like stainless steel can enhance durability, especially in harsh industrial environments. Lastly, consider the actuation method—whether manual, pneumatic, or electric—as this affects the valve's response time and overall performance in the system.

When selecting a pneumatic valve for industrial applications, understanding the various types and their functions is crucial. Pneumatic valves can be broadly categorized into directional control valves, flow control valves, pressure relief valves, and shut-off valves. According to a report by ResearchAndMarkets, the global market for pneumatic valves is expected to grow at a CAGR of 5.6% from 2022 to 2027, highlighting their significance in optimizing industrial processes.

Directional control valves, the most common type, dictate the path of compressed air within the system. They are available in configurations such as 2/2 or 5/2, catering to diverse applications, from simple on/off tasks to complex automation systems. Flow control valves, on the other hand, manage the speed of actuators by regulating air flow, ensuring that processes operate efficiently without oversaturation. Furthermore, pressure relief valves are essential for maintaining system safety by preventing overpressure situations, while shut-off valves play a critical role in isolating portions of the system during maintenance. Understanding these functions not only aids in proper selection but also enhances operational efficiency, leading to a more streamlined production environment.

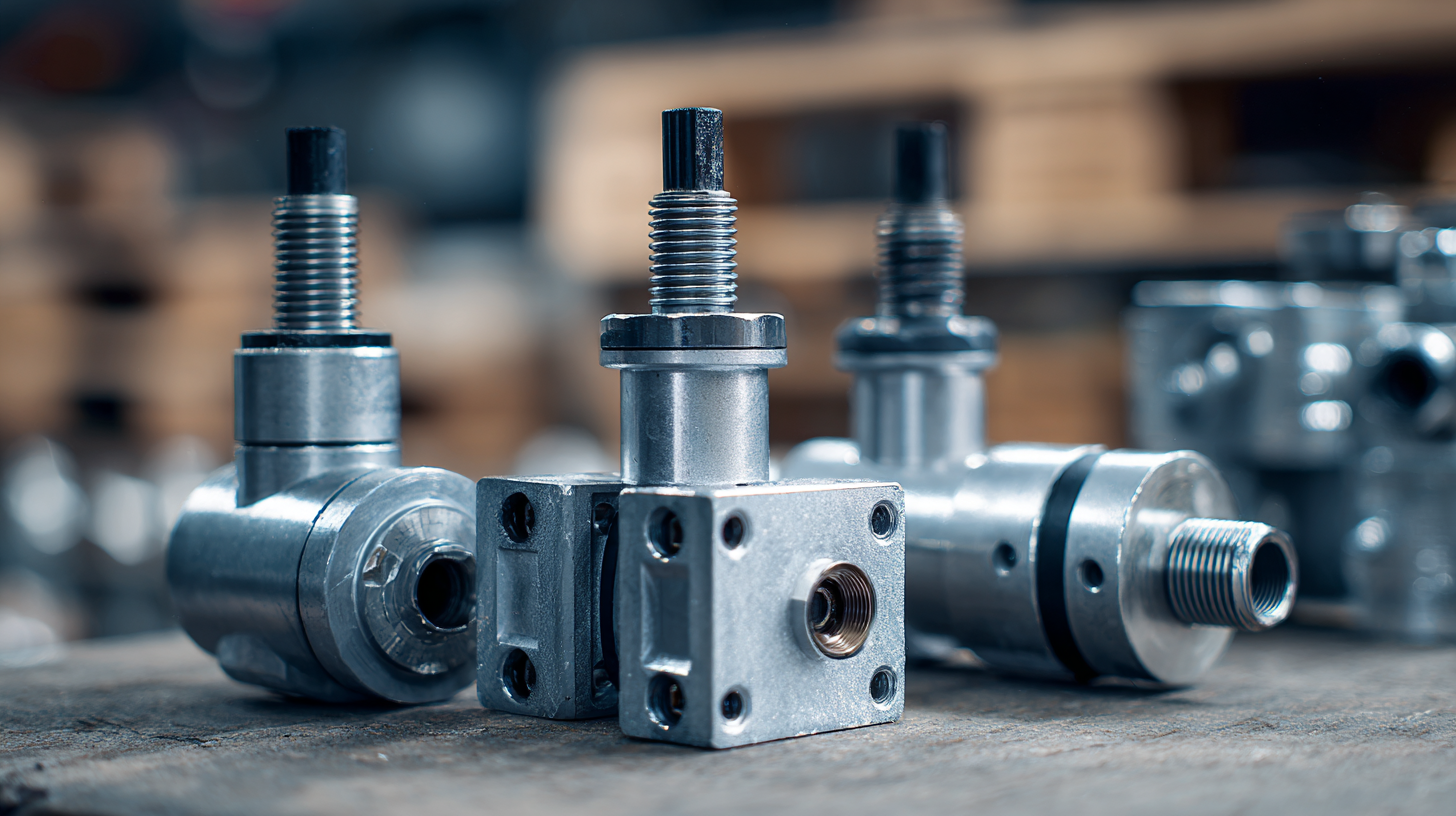

When selecting a pneumatic valve for industrial applications, determining the right size and capacity is crucial for optimizing performance. The size of the valve directly impacts the airflow and pressure within the system. To determine the appropriate valve size, you should consider the flow requirements of your application, including the volume of air needed and the pressure specifications. Utilizing tools such as flow rate calculators can help assess these requirements by examining factors like pipe diameter and system layout.

Additionally, it’s essential to evaluate the capacity of the valve in relation to both the maximum and minimum operating conditions of your system. This includes understanding the duty cycle, which indicates how frequently the valve will operate. Choosing a valve with a capacity that aligns with the system’s demand ensures that it can handle fluctuations without compromising efficiency. Accurate sizing not only enhances system reliability but also reduces wear on components, leading to improved longevity and performance in industrial settings.

When selecting a pneumatic valve for industrial applications, the materials used in construction play a crucial role in maintaining efficiency and reliability. The right material can significantly affect the valve’s performance, lifespan, and resistance to various operating conditions. For instance, stainless steel is often preferred for its corrosion resistance and robustness, making it ideal for harsh environments. Conversely, lightweight plastics may be suitable for less demanding applications where cost-effectiveness is a concern, but they might not withstand high temperatures or pressures.

Additionally, it is essential to consider compatibility with the media being controlled. For example, if the valve is handling aggressive chemicals, materials such as PTFE or specialized alloys might be required to prevent degradation and ensure a long operational life. The selection process also involves evaluating temperature and pressure ratings, as these factors will influence which materials will adequately perform without failure. Ultimately, choosing the appropriate materials for valve construction is vital not only for operational efficiency but also for minimizing maintenance costs and ensuring safety in industrial environments.

Choosing the right pneumatic valve for your industrial applications involves a careful balance between cost and performance. While it may be tempting to prioritize budget constraints, sacrificing quality can lead to increased downtime and maintenance costs in the long run. Understanding the specific needs of your application, such as flow rate, pressure, and environmental conditions, will help you make a more informed decision that maximizes both performance and value.

**Tip:** When comparing pneumatic valves, look beyond the initial purchase price. Evaluate the potential lifespan, reliability, and performance specifications. Investing a little more upfront in a high-quality valve can save money over time by reducing replacement frequency and minimizing operational failures.

Additionally, consider the operational efficiency of the valve. A more efficient valve can significantly impact your overall system performance and energy consumption, leading to cost savings in the long run.

**Tip:** Seek valves with features that enhance energy efficiency, such as reduced pressure drops and optimized actuation methods. This can lead to optimized operational costs, making your investment worthwhile.