In industrial applications, the efficiency and safety of processes heavily depend on the proper selection and implementation of control valves. According to a recent industry report by MarketsandMarkets, the global control valve market is projected to reach USD 8.4 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This growth underscores the significant role control valves play in various sectors, including oil and gas, water and wastewater management, and chemical processing. A well-chosen control valve can optimize flow control, enhance process efficiency, and minimize operational risks.

Selecting the right control valve is more than just an engineering decision; it is a pivotal factor that impacts overall system reliability and operational costs. Factors such as valve type, size, material, and actuation method must be meticulously considered to align with specific application requirements. An incorrect choice can lead to significant downtime, increased maintenance costs, and even safety hazards. By following strategic guidelines tailored to the unique demands of their applications, industry professionals can navigate the complexities of valve selection, ultimately contributing to the long-term success and safety of their operations.

Control valves play a crucial role in process systems, acting as the primary mechanism for regulating fluid flow and pressure. They are vital components in various industries, including chemical processing, oil and gas, and water treatment, where precise control can significantly impact operational efficiency and safety. By adjusting the flow rate and pressure of fluids, control valves help maintain optimal conditions for chemical reactions, enhance system performance, and ensure compliance with safety standards.

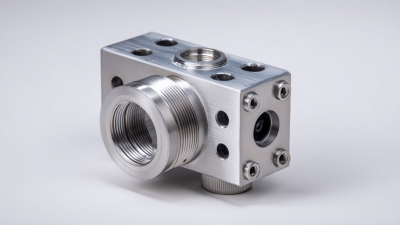

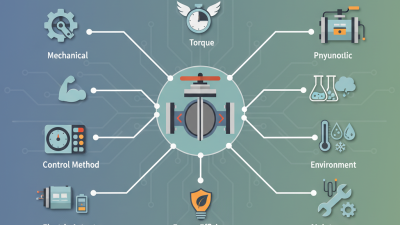

Understanding the specific requirements of an application is key when selecting a control valve. Factors such as the type of fluid being controlled, temperature, pressure, and flow characteristics must all be considered. The valve's construction materials also matter, as they need to withstand the corrosive properties of some fluids while maintaining durability under high-pressure conditions. Additionally, the control method—whether it be electric, pneumatic, or hydraulic—plays a decisive role in achieving the intended level of accuracy and responsiveness in the system. By carefully analyzing these factors, engineers can select the most suitable control valve to optimize process performance and reliability.

When selecting the right control valve for your application, it’s essential to consider several key parameters that can significantly impact performance and efficiency. One of the most critical factors is the valve’s sizing and flow characteristics. According to a study by the Flow Control Institute, improper sizing can lead to inefficiencies of up to 20%, emphasizing the need for precise calculations based on the required flow rates and pressure drops. Factors such as the valve’s Cv rating, which indicates its flow capacity, must align with your process requirements to ensure optimal operation.

Another vital parameter is the material compatibility of the valve with the fluid being controlled. A report from the International Society of Automation highlights that nearly 30% of valve failures are due to corrosion and wear, stemming from improper material selection. For instance, if your application involves corrosive substances, selecting a valve made from materials like stainless steel or specialized alloys can prolong the valve’s lifespan and minimize maintenance costs. Additionally, understanding the operating temperature and pressure is crucial, as exceeding the valve’s specifications can lead to catastrophic failures, underscoring the importance of adhering to manufacturer guidelines and industry standards.

| Parameter | Description | Importance Level | Recommended Valve Type |

|---|---|---|---|

| Flow Rate | The volume of fluid passing through the valve per unit time. | High | Ball Valve |

| Pressure Drop | The difference in pressure across the valve. | High | Globe Valve |

| Temperature | The operating temperature of the fluid. | Medium | Butterfly Valve |

| Fluid Type | The nature of the fluid (liquid, gas, corrosive, etc.). | High | Check Valve |

| Control Method | The type of control strategy employed (manual, pneumatic, electric). | Medium | Electric Actuated Valve |

| Size | The nominal size of the valve related to the pipe size. | Medium | Flanged Valve |

| Environment | The conditions surrounding the valve (temperature, pressure, presence of dust). | High | Sealed Valve |

| Budget | The financial constraints for purchasing the valve. | Low | Standard Valve |

| Maintenance | Ease of maintenance and serviceability. | Medium | Serviceable Valve |

| Regulatory Compliance | Suitability meeting industry regulations and standards. | High | Certified Valve |

When selecting a control valve for a specific application, understanding the different types of control valves and their appropriate uses is essential.

Gate valves are commonly used for on-off control as they provide minimal resistance to flow. However, they are not ideal for throttling purposes because their design does not allow for precise flow regulation.

For applications requiring flow modulation, globe valves come into play. Their design facilitates significantly better control of flow rates, making them suitable for regulating pressure or flow in pipelines.

Another prevalent option is the ball valve, known for its durability and reliability. Ball valves are typically employed in systems where a quick shut-off is necessary, and they are suited for various services,

including water, oil, and gas. For more complex applications, such as those experiencing varying pressure and flow conditions, a butterfly valve may be the right choice.

These valves offer a compact design and can control flow efficiently across a wide range of operations.

Understanding these differences allows engineers to make informed decisions when choosing the right valve type for their system requirements.

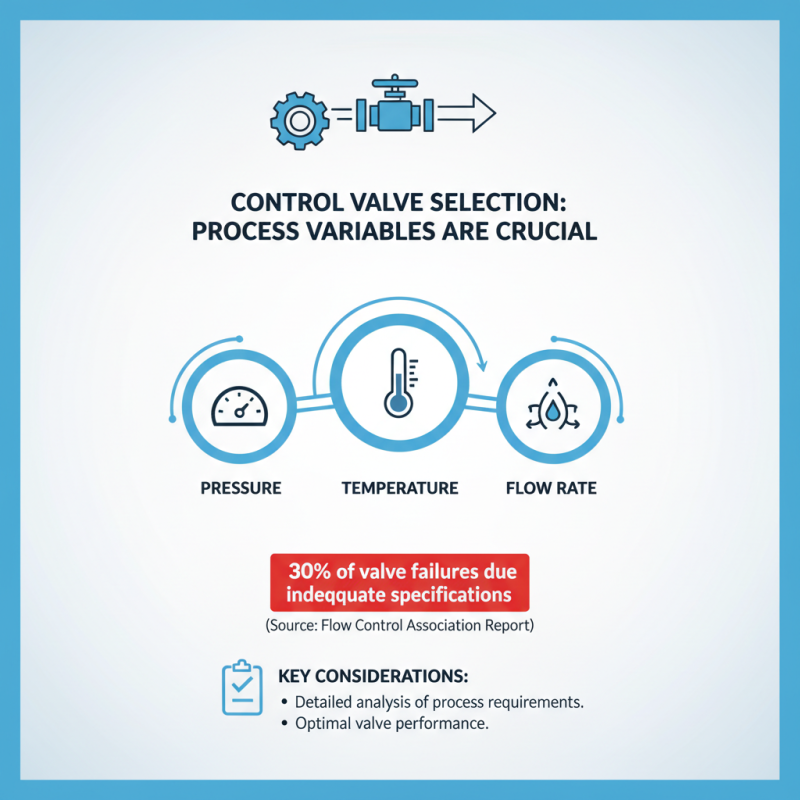

When selecting the right control valve for a specific application, evaluating process variables is crucial for ensuring optimal valve performance. Key variables such as pressure, temperature, and flow rate significantly influence the choice of valve. For instance, according to a report by the Flow Control Association, approximately 30% of valve failures can be attributed to inadequate performance specifications aligned with these parameters. This highlights the necessity of a detailed analysis of process requirements before making a selection.

Moreover, understanding the dynamics of the fluid being controlled is equally important. Factors such as viscosity, density, and the presence of particulates can severely affect valve operation. A study by the International Society of Automation indicates that nearly 40% of industrial malfunctions are directly linked to the inappropriate control of fluids based on their properties. Therefore, proper evaluation of these process variables not only ensures efficient operation but also prolongs the lifespan of the equipment, resulting in reduced operational costs over time. Implementing a thorough assessment prior to valve selection can thus lead to enhanced reliability and performance in complex industrial environments.

When selecting the right control valve for your application, maintenance and reliability play crucial roles in ensuring optimal performance and longevity. A valve's design and material selection can significantly influence its durability, allowing it to withstand environmental factors such as temperature fluctuations, pressure variations, and corrosive substances. For instance, valves made from robust materials like stainless steel or specialized alloys may provide better resistance to wear and tear, thus reducing the frequency of maintenance interventions. It's essential to assess the operating conditions of the system and choose a valve that not only fits the specifications but also aligns with the expected maintenance cycle of the facility.

Reliability is equally important when considering control valve selection. The chosen valve must operate consistently under the specified conditions without failure or degradation. Factors such as valve-actuator responsiveness, sealing technology, and flow characteristics should be evaluated. A valve that requires frequent adjustments or presents a risk of failure may lead to operational downtime and increased repair costs. By prioritizing reliability in valve selection, organizations can minimize interruptions, enhance process efficiency, and ultimately achieve a more cost-effective solution in the long run.